MINING

Walling Stone

Variable production of walling stone is carried out.

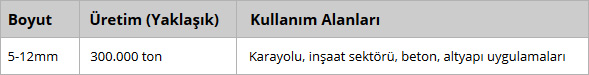

| Production (Approximate) | Usage Areas |

| 100.000 ton | Highways, construction industry, concrete, infrastructure implementations |

Production in our stone quarries is carried out by open operation method. After the greywacke material on the stone is excavated, 12-15 meters deep holes are drilled by using the drilling machine (rock) and the stone is exploded by using emulsion dynamite, anfo and delayed capsule. The obtained material is transported to the crushing & screening plant by loading them on trucks by using wheeled palletted loader machines. The material is sorted into suitable dimensions in the crushing & screening plant and classified as dust, number 1 stone chips, number 2 stone chips and number 3 stone chips and other material. The materials sorted into the silos are transported to the customers by trucks and the remaining material is stacked separately on the stockyards.

There are limestone and sandstone rocks within our licensed area. The rock, which we, Su-Stone, have in our production area, is mainly sandstone (sublitarenite).

Physical Characteristics

Chemical Characteristics

| Abrasion Loss | Frost Resistance | Specific Gravity | Water Absorption | Color |

| 22,1 | 2,8 | 2,71 | 1,1 | Grayish Black |

Chemical Characteristics

| Component | SiO2 | A1203 | Fe203 | Mn0 | CaO | MgO | K2O | Na2O | A.Z. | TOTAL |

| 65,23 | 12,53 | 6,05 | 0,26 | 4,30 | 3,81 | 0,92 | 2,02 | 4,75 | 99,87 |